Educational Sessions

2026 BOILER Expo features insightful educational content, and unique opportunities to learn about today’s solutions to address boiler room needs and challenges.

Get Ready to Ignite Your Knowledge at the 2026 ABMA BOILER Expo in Nashville!

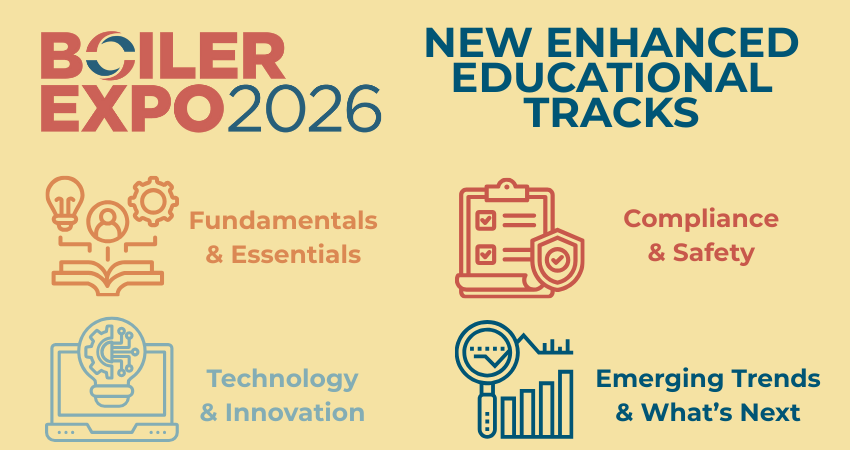

The 2026 BOILER Expo will have an exciting and revitalized educational focus, expanding our offerings from previous expos and feature over 20 breakout sessions across four key educational tracks. In addition, the Expo will feature new hands-on boiler training opportunities, and expanded pre-conference workshops, ensuring an enriching experience for all attendees.

Four Key Educational Tracks:

Fundamentals & Essentials: Attendees will gain crucial insights into boiler selection, effective operation, proper maintenance, and strategies to maximize efficiency. This foundational knowledge is designed for both newcomers and seasoned professionals looking to hone their skills.

Safety & Compliance: Ensuring the highest level of boiler safety is paramount. Participants will delve into effective project readiness, understanding the significance of boiler safety, and staying compliant with ever-evolving codes and regulations that govern the industry.

Technology & Innovation: The industry is evolving rapidly, and our sessions will cover the latest advancements in boiler technology. Learn how innovative solutions are being developed to meet and exceed customer needs, helping to foster a more efficient and sustainable boiler room environment.

Emerging Trends & What’s Next: Explore how the boiler industry is shaping its future through hybrid systems and alternative fuel sources. Attendees will be introduced to new trends that are redefining the boiler landscape and paving the way for tomorrow’s boiler room.

“As we gear up for the 2026 ABMA BOILER Expo, I invite everyone to come together to enhance our knowledge and experience the innovation in our industry. The exciting enhancements to our educational program promise to deliver invaluable insights and foster collaboration. We are looking forward to the opportunity to elevate boiler expertise and propel the boiler industry forward!”

— Dustin Divinia, President of Vector Systems & Chair of the BOILER Expo Advisory Committee.

Pre-Conference Workshops are $99/ea

Boiler Types & Applications

Presented by Jude Wolfe, WARE & Boiler University

With over 25 years of field service experience, Jude has worked on nearly every type of boiler system. Known for his calm, practical teaching style, he helps students connect real-world service skills in the boiler room.

WARE brings their expertise from Boiler University to the BOILER Expo for this four-hour pre-conference workshop on boiler types and applications.

This workshop offers an overview of boiler and burner types for a variety of applications along with insights on vessel selection, feedwater requirements, emissions and controls.

Attending this workshop will prepare you for your next boiler purchase or retrofit project.

Attending this workshop will prepare you for your next boiler purchase or retrofit project.

Boiler Water Treatment Workshop

Presented by AWT – The Association of Water Technologies

This workshop is designed to give boiler operators, managers, service professionals and others a complete understanding of the critical role water treatment plays in safety, efficiency, and reliable operation of boilers. Rather than focusing on theory alone, the program emphasizes real-world challenges, practical solutions, and proven strategies that directly impact day-to-day operations and efficiency in the boiler room.

Topics Addressed Include:

The Economics of Boiler Water Treatment: Uncovering the True Cost of Operation and the Key Drivers of Safety and Efficiency

Boiler Feedwater: Conditioning Techniques That Keep Your System Safe, Efficient, and Long-Lasting

Waterside Boiler Failures and How to Prevent Them: A Practical Guide to Common Causes and Proven Prevention Strategies

Regulatory Compliance in Boiler Water Treatment: Standards, Guidelines, and Operational Excellence

Speakers & Topics

American Society of Power Engineers (ASOPE)

The Art of Replacing Boilers in a Centralized Plant Without Impact on Production Needs

Jay Ehrfurth, ASOPE National President

Mr. Ehrfurth has over 40 years of providing training and operations/maintenance consulting in the thermal world concentrating on central plants and distribution systems. Before retiring from Boldt, Jay’s role as VP-Energy supported the repair, modification or construction of centralized thermal facilities for hospitals, industrial, higher educational, and correctional facilities. Jay has personally managed over $1 billion in power related projects. Prior to Boldt, Jay served as the State Chief Power Plant Engineer for the WI DOA. Jay’s responsibilities included the monitoring of central plant performance, fuel procurement, plant emissions, and construction projects for 33+ state thermal plants. Jay is a Licensed Professional Engineer (Mechanical – WI), a Certified Energy Manager, holds an ASOPE-Master Chief’s License and Technical Instructor credential. Jay is on the board of directors for the Wisconsin Boiler Inspectors Association (WBIA), and American Society of Power Engineers (ASOPE) – currently serving as ASOPE National President.

Autoflame Engineering

Emissions Standards and Monitoring Technologies: Staying Compliant and Future-Ready

Tom Garrett & William Evans

Tom is the North American Sales Director at Autoflame Engineering. Having joined the company in July 2017 with a BEng Hons in Aerospace Engineering, Tom oversees and manages the day-to-day operations of Tech Centres and OEMs in North America. His experience spans from high-level technical presentations and explanations, to advising on complex installations, instructing on industry best practices, building control panels, and technical account management.

In addition to looking after more than 70 partner companies from around the world, Tom spends a lot of his time travelling around North America, conducting 2-day Training Schools with Tech Centers and End Users that focus on optimizing plant efficiency and reducing energy consumption. Training includes a balance of high-level Autoflame subjects and hands-on practical demonstrations, as well as industry-relevant combustion and electrical wiring topics.

William Evans is Technical Account Manager for North America at Autoflame Engineering Ltd., a world leader in combustion management systems for commercial and industrial applications. He joined Autoflame in 2024 after completing his degree in Mechanical Engineering with honors, entering the company through their comprehensive graduate program. During his graduate program, William received in-depth training on boiler room operations, including steam systems, heat management, and electrical systems. His placement in the panel shop provided him with valuable experience in electrical interference issues and electrical technical knowledge, building a strong foundation in the critical components of combustion control systems.

Currently, William assists in the management of the North American market, working collaboratively with Autoflame's extensive network of Tech Centres and OEM partners across the region. His responsibilities include technical support, account management, and providing comprehensive training on Autoflame's advanced Micro-Modulation systems. In addition to his technical responsibilities, William actively identifies potential opportunities to expand the Autoflame Tech centre Network, fostering new relationships and partnerships. While new to the steam and boiler industry, William brings fresh perspectives to the technical elements of Autoflame's combustion management systems, combining his mechanical engineering background with practical experience gained through the company's rigorous training programs.

Chicago Blower

The Truth About the Fan Industry's Unrealistic Sound Ratings

Scott Kossman, President

With over 35 years of experience in the engineering and manufacturing industry, Scott has dedicated his entire career to driving innovation, operational excellence, and employee-focused leadership. As President of Chicago Blower Corporation for the past five years, Scott has transformed the company from regular employee turnover a stable “want to work at” environment, expanding its global market in 22 countries with licensed partners worldwide.

Clark-Reliance

ASME Boiler and Pressure Vessel Section I Requirements for Level Instrumentation

Nate Klein, Product Manager

Nate Klein is the Reliance Product Manager at Clark-Reliance®, where he leads strategic product development and market positioning for the company's flagship product line offering boiler trim products for water level monitoring and control. With over ten years of experience in engineering and boiler systems, Nate brings a unique blend of technical expertise, customer insight, and cross-functional leadership to his role.

He is responsible for driving innovation through new product initiatives, conducting market and competitive analysis, and aligning product strategy with emerging technologies and customer needs. Nate also plays a key role in the boiler industry by presenting ASME BPV Section I requirements for level indication to refineries, power plants, boiler insurance providers, and state inspection agencies.

Prior to his current role, Nate began his career at The Babcock & Wilcox Company, where he held roles in field service and applications engineering. His work included commissioning large-scale emissions projects, conducting boiler inspections during outages, and collaborating with multidisciplinary teams to deliver complex engineering solutions.

Elliott Tool Technologies

Mastering the Heavy Wall Challenge: Tooling and Techniques for Successful Drift Rolling

Brandon Fultz, Application Specialist

Brandon Fultz is an Application Specialist at Elliott Tool Technologies with over 15 years of experience in industrial sales, technical support, and manufacturing solutions. He has worked extensively in equipment design, project management, and customer training across both domestic and international markets. Brandon’s background in manufacturing processes and machinery design allows him to deliver practical, customer-focused solutions and support successful product launches.

Emerson

Boiler Valve Operations

Tim Dwyer

Tim Dwyer is a Business Development Manager of Steam and Industrial Regulators with Emerson. He covers pressure control devices and steam equipment. Tim has been with Emerson for 9 years and held multiple roles that have given experience with many of the various valves found in process industries. He is involved in the FCI standards committees for various steam valves used in industry and ABMA. Tim has a BS in Mechanical Engineering from Iowa State University and is a Certified Energy Manager.

Russell Wilfong

Russell Wilfong has nearly 20 years of experience in the power and steam industry and is the Business Development Manager at Equipment & Controls, Inc. (ECI), where he helps customers optimize the safety, reliability, and efficiency of steam and combustion systems, including boilers, heaters, and other industrial applications. Russell brings deep technical expertise in boilers and combustion, commissioning, and construction management to identify opportunities, develop effective proposals, and deliver practical, value-added solutions. Drawing on experience from previous roles with Babcock & Wilcox, NRG, and Babcock Power, he is passionate about providing innovative solutions that enhance performance and support the long-term sustainability of his customers’ operations.

E-Tech

New Heat Recovery Retrofit into Legacy Systems

Jamie Tighe

An experienced engineer with more than 35 years in the power and process industry, Jaime has built a career specializing in thermal, pressure vessel, and structural design. He has been with E-Tech, Inc. since 1988, where he applies deep expertise in energy systems, power plants, renewable energy, and project management to support complex engineering projects. His long-standing industry experience and strong technical background make him a trusted professional in delivering reliable and effective engineering solutions.

Gestra

Improve Boiler Efficency Through TDS Control

Dominik Mahne

Dominik Mahne is Sector & Business development Manager Boiler house at GESTRA in Bremen, Germany, specializing in steam and condensate systems. With over 10 years of experience, he supports industrial customers in optimizing boiler house operations with a focus on energy efficiency, safety, and regulatory compliance.

Dominik works closely with end users across various industries to implement smart control solutions for blowdown management, TDS control, and continuous level monitoring. He supported numerous customer-focused projects that improve system reliability and reduce operational costs, while ensuring alignment with standards for boiler such as UL60730 or EN 12953.

His expertise includes digitalization of boiler systems, integration of advanced technologies like conductive level limiting, capacitive level sensing, and translating technical requirements into practical, user-friendly solutions. Dominik regularly contributes to technical trainings, customer workshops, and market analysis, helping clients navigate the evolving landscape of boiler technology.

Bernie Sapp

Paul Bernard “Bernie” Sapp is a seasoned technical sales and operations leader with over two decades of experience driving growth and operational excellence in the industrial valve, instrumentation, and process automation sectors. With a strong foundation in mechanical products and process control, Bernie has consistently delivered results through his deep technical knowledge, strategic vision, and hands-on leadership.

At FCX Performance, Bernie led the reorganization of sales territories to maximize efficiency, successfully integrating and aligning multiple teams and establishing new P&L structures. His technical acumen enabled him to streamline inside sales operations and foster cross-functional collaboration, ensuring optimal resource allocation and improved sales performance.

During his 20-year tenure at Spirax Sarco Inc., Bernie held progressive leadership roles, including Direct Strategic Account Manager, National Food and Beverage Manager, Midwest Regional Sales Manager, and Energy Services Manager. He spearheaded the implementation of new sales force structures, aligning strategic and distributor teams to better serve end users. Bernie’s technical expertise was instrumental in evaluating workload, contribution margins, and resource needs, leading to data-driven workforce planning and increased return on investment.

Bernie’s technical leadership extended to process improvement initiatives, where he identified inefficiencies and implemented changes that enhanced operational workflows. He managed complex, multi-million-dollar projects, coordinated inter-departmental teams, and drove significant reductions in operational losses. His ability to analyze employee strengths, territory dynamics, and distribution networks resulted in market share gains and improved sales coverage.

Throughout his career, Bernie has demonstrated a commitment to technical excellence, continuous improvement, and customer-focused solutions. His expertise in sales management, process optimization, and technical training has made him a trusted advisor and leader in the industrial automation industry.

Nationwide Boiler

Emissions Regulations, Control Strategies, Lessons Learned

Jim Lieskovan, Vice President of Sales

Jim Lieskovan has worked within the Boiler Industry for more than 40 years. Beginning his career as a Field Service Technician, Jim and his partners built one of the larger Boiler / Burner Sales and Service organizations in California. Since the late 1980’s, Jim worked with Nationwide Boiler as a Contractor and as a customer, participating in many Rental Boiler and CataStak™ SCR sales, installation, and start-up projects. In 2014, after selling his own Company, Jim joined the Nationwide Boiler Team, bringing 30 plus years of Technical, Managerial and Sales experience to his current role as Vice President of Sales.

Preferred Utilities

Understanding the Fundamental Safety Principles of Burner Management Systems

David Eoff, Vice President of Sales & Service

David Eoff is a mechanical engineer with 34 years of experience in the electric power, industrial boiler, and commercial fueling industries. He currently serves as Vice President of Sales and Service, where he specializes in the design and commissioning of diesel fueling systems for emergency generators and dual-fuel boilers. His work supports mission-critical applications across hospitals, universities, data centers, and secure government facilities.

R.F. MacDonald

Hybrid Systems with Gas or Electric Boilers Plus Heat Pumps

Matt MacDonald, Vice President of Sales

Matt MacDonald is a seasoned professional with a robust educational and career background. He earned his Bachelor’s degree in Economics from Standford University in 2003, followed by a Juris Doctorate from the University of Virginia in 2010. Matt’s early career included clerking for a federal judge in Alexandria, VA and working as an associate at a prominent law firm in Washington, D.C., before joining RFM in 2014.

At RFM, Matt started as a sales engineer in the Hayward office, where he focused on business development, collaborating closely with engineers and desgin/build contractors. His expertise and leadership skills quickly propelled him to the role of Business Development Manager for the HARP office in 2016, where he successfully built and managed the Business Development Team. By 2021 he was promoted to VP of Sales for the New Equipment Team. In this role, Matt launched significant partnerships with manufacturers like TACO and Galletti and continues to work directly with RFM’s manufacturers to develop sales strategies, build forecasts, monitor pipelines, implement training, and serve as the company’s key point of contact.

Rogue Combustion

CFD Modeling

Troy Edens, Director at Rogue Combustion

Over 20 years of experience in design and operation of fired equipment. Including Boilers, Dryers, Thermal Oxidizers, Evaporators, and Cement Kilns.

Last 3 years working for Rogue Combustion as a ClearSign partner in the development of the Rogue Burner System with ClearSign Core Technologies(TM).

Steamworks

Top 10 Must-Have Skills for Boiler Operators

Jon Kapel, CEO

Jon Kapel is husband to his high school sweetheart and a father of four. In his free time, he is the CEO of Steamworks and author of Skill Stigma. Steamworks provides made-to-order training, consulting, and operations for steam systems across the US and beyond. He and hs team values imparting competency and confidence in steam boiler safety, operation and maintenance. Hundreds of 5-star reviews describe how Steamworks trainings leave students with renewed excitement about their role in the steam industry and how their approach to training is fresh. Beyond the steam industry, Jon’s book. Skill Stigma, breaks the myths about work in the skilled trades and informs educators on how to present the skilled trades to students as a viable career path for emerging generations. He enjoys sharing his story about being pleasantly hoodwinked into a career in the skill trades.

Weishaupt

Combustion Theory, Low NOx Legislation and Low NOx Burner Technology

Robert Reid, Manager of Technical Services & Training

With 30 years in the burner and burner related industry locally, in Europe and across North America, Robert’s industry knowledge is derived from years spent in technical sales, applications, education and R&D. Robert is currently the Manager of Technical Services and Training with Weishaupt Corporation in Mississauga, Ontario, Canada.

Superior Boiler

Firetube vs. Watertube: The Right Boiler Type for Your Application

Don Whitman, President & CEO

Don Whitman serves as President & CEO of Superior Boiler, bringing extensive and broad experience in the industrial boiler industry. He oversees Superior’s operations and growth, including leading the successful relocation of the company’s Richmond, Virginia operations to Hutchinson in 2020. In recent years, Whitman continues to drive division growth while improving operations across the business.

Mokhtar Matallah, Vice President of Engineering

Mokhtar Matallah is Vice President of Engineering at Superior Boiler Works, Inc., where he leads engineering efforts for firetube and industrial boiler solutions. Based in Hutchinson, Kansas, he brings extensive technical leadership to the company’s product design and development, helping drive quality and performance in engineered energy systems. He holds a degree from the University of Tulsa and combines industry expertise with a commitment to innovation in boiler engineering and manufacturing.

NBBI

Properly Preparing a Boiler for Inspection Panel

MODERATOR

John Burpee, Past Chief Maine, Past Chairman of the National Board, and current National Board Jurisdictional Liaison

Jon Kapel is husband to his high school sweetheart and a father of four. In his free time, he is the CEO of Steamworks and author of Skill Stigma. Steamworks provides made-to-order training, consulting, and operations for steam systems across the US and beyond. He and hs team values imparting competency and confidence in steam boiler safety, operation and maintenance. Hundreds of 5-star reviews describe how Steamworks trainings leave students with renewed excitement about their role in the steam industry and how their approach to training is fresh. Beyond the steam industry, Jon’s book. Skill Stigma, breaks the myths about work in the skilled trades and informs educators on how to present the skilled trades to students as a viable career path for emerging generations. He enjoys sharing his story about being pleasantly hoodwinked into a career in the skill trades.

PANELISTS

Jimmy Watson, Chief Boiler Inspector State of Tennessee

Jimmy Watson is the Chief Boiler Inspector for the State of Tennessee, where he oversees boiler and pressure vessel safety and compliance statewide. After completing an apprenticeship with the Tennessee Department of Labor and Workforce Development, he advanced to his current role, leading a team of 18 inspectors and apprentices responsible for conducting critical safety inspections across a wide range of facilities. In addition to managing inspections and mentoring the next generation of inspectors, Watson represents Tennessee on the National Board of Boiler and Pressure Vessel Inspectors, contributing to national dialogue and standards that support public safety and regulatory excellence within the boiler industry.

Alexander Cass, Asst. Chief Boiler Inspector State of Tennessee

Alexander Cass is the Assistant Chief Boiler Inspector for the State of Tennessee. His role involves overseeing the inspection process for boilers and pressure vessels, ensuring compliance with safety regulations and standards. Cass is part of a team that conducts inspections, issues certificates, and manages the licensing of repair and erection companies in Tennessee. The Boiler Unit is responsible for protecting the public from potential hazards associated with the operation of these devices. For more information on the inspection process, licensing, and other related matters, individuals can refer to the official Boiler Unit website or contact the unit directly.

Ed Verderose, Vice President – Business Development, Industrial Steam Boiler Corporation

Edward Verderose Jr. is Vice President of Business Development at Industrial Steam Boiler Corporation, where he focuses on commercial and industrial boiler safety, code compliance, operational efficiency, and sustainability initiatives. He brings decades of hands-on and leadership experience across boiler design, installation, integration, and operation, and is a frequent national speaker and technical trainer. Edward serves on the ABMA Board of Directors and is actively involved with the National Board of Boiler and Pressure Vessel Inspectors (NBBI), contributing to the advancement of best practices and the future of the boiler industry.

William (Dirk) Chandler, Loss Control Inspector, Hartford Steam Boiler

My steam boiler experience began at a young age, driven by a passion for historic steam locomotives. In 2000, I was hired as a locomotive fireman, shoveling coal to feed the boilers, and was promoted to steam locomotive engineer in 2001. While working with various railroads, I gained experience in locomotive rebuilds, railcar maintenance, track replacement, and eventually led the machine and fabrication shop. In 2009, I joined Hartford Steam Boiler as a Loss Control Inspector, a position I continue to hold today. My wife, April, and I own and operate a farm in East Tennessee where we maintain several historic steam boilers, including sawmill engines, a steam roller, and a steam-powered machine shop. Together, we also constructed and operate a full-size railroad on our property for friends to enjoy. I have held the AI boiler commissions in both Tennessee and Kentucky since 2009.

Shoplogix

Innovative Steam Trap Monitoring: Battery-less & Wireless

Todd Klanderud

Highly skilled and dedicated professional with over 30 years of combined experience in mechanical systems, specializing in steam systems for over two decades. Brings a disciplined background from U.S. Navy service into a robust career as a Steamfitter and steam systems specialist. Expert in the installation, maintenance, troubleshooting, and monitoring of complex industrial steam and piping systems. Proven ability to improve system efficiency, reliability, and safety across a vast array of demanding industries. A strong problem-solver committed to customer education and achieving operational excellence.